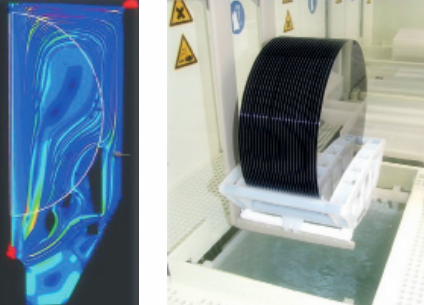

Drying system CSE

Advantage

The CSE drying system uses IPA and N2 atomization, as well as the shape of a wafer from water.

The technique of surface tension drying

Drying technology suitable for maximum size 300mm wafer

> can be single device or integrated in wet equipment

> the best area of land

Mature process

No water trace

No fragments

Features and advantages

Application

Polished chips, integrated circuits, MEMES, LED, photovoltaic, glass substrates

General characteristics

> can dry 25 to 50 pieces of wafer with a maximum diameter of 300mm at the same time

> for standard high or low side flower baskets

Specifications

Process time: generally < 10 minutes, changed by the menu of the selected process

Hydrophilic wafer: less than 10 increase @ 0.12 M

Hydrophobic wafer: less than 30 increase @ 0.12 M

Metal content: any metal is less than or equal to 1 - 1010 atoms / cm2

Dry spots: no spots after drying

IPA consumption: less than 30 ml / run

Go to the edge: 3 mm

Graphical user interface

> based on B&R PLC

Edit menu

> > automatic recording (EOR, ERR etc.)

> multilevel cipher

General installation parameters

Size: 660 x 1440 x 2200 (long x wide x high)

Standard voltage: 3 x 400 VAC

Rated power: 50 Hz

Standard current: 3 x 33 A

Train

Operation, maintenance, process training

standard

> CE

> > Semi S2 and S8

> FM 4910

> > SECS/GEM

option

Laminar flow

IPA concentration monitoring system

> hot N2

> UPS component

reliability

MTBF > > 800 H

The average time interval of more than 300 auxiliary > H

But the running time is more than 97%.

The drying system of equipment more relevant information can focus on the CSE website CSE (www.hlkncse.com), now 400-8768-096 hotline immediately available free solution for semiconductor cleaning equipment.