Wet Equipment-CSE

Wet equipment Nantong CSE Semiconductor Equipment Co. Ltd. is suitable for many applications, including cleaning, etching, stripping, developing etc.

Advantages of CSE wet process equipment

> wet equipment is suitable for many applications, including cleaning, etching, degumming and developing

> covers an area of small area

> reliability is strong

> unique module structure

Easy maintenance and maintenance, low cost

> maximum compatible application

Each module's separate air exhausting device

> easy to install and update modules based on the manipulator system

Characteristics and advantages

Many different cleaning processes, such as RCA, IMEC, Pre-Diffusion, Pre-Metal, and various etching processes, including oxidation

Compounds, nitrides, polysilicon, metals, silicides, and nitric compounds

General characteristics

> for standard or low side flower baskets

Individual modules of each module; effective discharge of acids, alkalis, neutrality, and gas produced by the solvent

The process of drying out

Intelligent self rescue and emergency stop function of wafer

Powerful, simplified scheduler

Process control ability

The batch follows the whole process

Setting parameter tracking, including temperature, flow, resistivity, chemical measurement, etc.

> batch tracking, error information documents, process real-time monitoring, user level setting

Graphical user interface

> based on the B&R CPU and IPC interface, the size is 17 inches

Edit menu

> real time flowchart

Auto save (EOR, ERR, ChemLog, etc.)

> multilevel cipher

> network remote control

Train

Operation, maintenance and process training

option

> automatic wafer loading and transmission

> wafer ID recognition

> flower basket buffering function

> dry into wet out and wet to dry out (manually loading the wafer area ozone system)

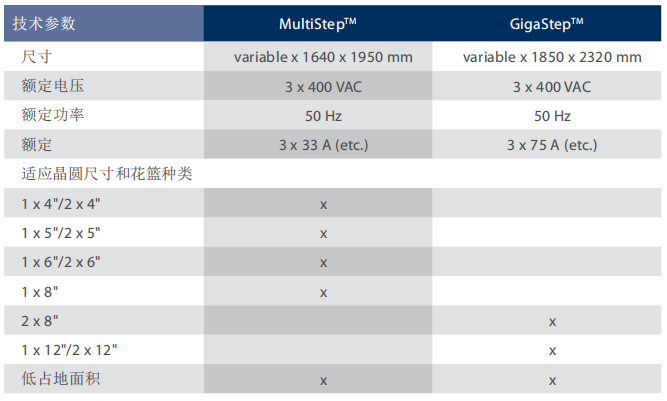

Suitable for size (150, 200 or 300 mm)

Waste liquid management system

Locally installed chemical preparatory grooves for dilution, mixing and chemical liquid preheating devices

Deionized water heating system

Laminar flow

Concentration monitoring system

> deionized water supply point filtration

Fire extinguishing device

> components

> and so on.

reliability

MTBF > 800 H

The average time interval of more than 300 h auxiliary

But the running time is more than 97%

Assembly and shipping

Semiconductor wet cleaning equipment more concerned about the Nantong CSE semiconductor equipment limited company website: www.hlkncse.com; now 400-8768-09618913575037 consulting can obtain the relevant project in wet cleaning equipment for free